Ht200

Manual

Obslužný návod

Ht200

Programmable PID controller for industrial applications

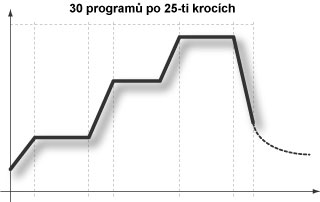

• programmable controllers (30 programs with 25 steps)

• PID / ON/OFF switching / 3-way control

• 1 input, 7 outputs

• LAN interface (on the rear panel)

• USB port (on front panel)

• 2 communication lines EIA485

• 2 digital inputs

• datalogger of process values (10000 logs)

• datalogger of messages about operation of the device (5000 logs)

• datalogger of ambient temperature (5000 logs)

• starting a program by the keyboard

• starting a program by real-time clock

• 3 years warranty

• guaranteed servicing

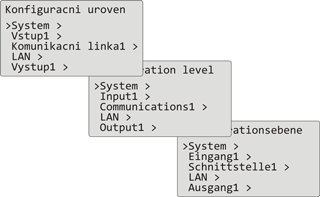

How to operate the controller

|

|

|

Controlling of stp point

|

• by program control (30 programs with 25 steps) • maintaining the set point Starting a program • starting a program by the keyboard • starting a program by real-time clock • by digital input • through the communication line |

|

Controlling

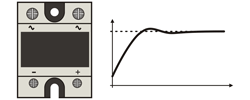

The controller can operate the thermal system with the following types of controlling:

|

This mode is most used. It enables controlling to zero deviation. As an output it can be applied solid-state, relay, voltage or current output. |

|

|

ON/OFF switching Simple way of controlling, it is not possible to reach the zero deviation. |

|

|

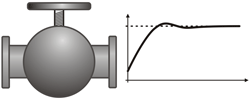

3-way step controlling PID control with 2 outputs for adjusting of valves. Position of the valve is calculated from the time of transition. |

|

Dataloggers in the controller

The controller Ht200 stores data into 3 dataloggers:

|

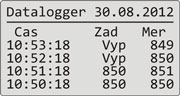

Datalogger of process values stores: • measured and set point value of the controller Ht200 • measured values from as many as 7 "Slave" controllers • status of the external energy meter • number of the running program Maximum amount of logs is 10000. |

|

|

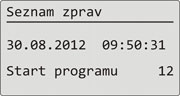

Datalogger of messages stores: • changes in the parameters setting in configuration and operational level • time of start / end or interruption of a program • exceeding of alarm limits • ... Maximum amount of logs is 5000. |

|

|

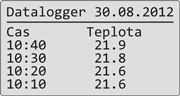

Datalogger of ambient temperature stores: • ambient temperature, it means the temperature at which the controller works Maximum amount of logs is 5000. |

|

Stored values can be transferred to external FLASH memory or though the communication line to PC.

Diagnostics of the controller operation

The controller saves the important information about its activities ( configuration, changes in setting of parameters, ambient temperatures …).

These information can be easily copied to external FLASH memory into „INFO“ file and can be sent to the supplier of the equipment for making diagnostics of the operation of the equipment.

|

INFO file comprises: • configuration and name of the controller • information about exceeding the ambient temperature • setting of the device (parameters of configuration and operation level) • messages of the activities of the device (change in setting, starting a program, ...) • datalogger of ambient temperature |

|