Ht205

Manual

Obslužný návod

Ht205

Programmable PID controller for industrial applications

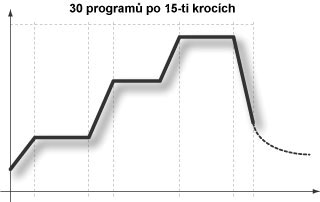

• programmable controller (30 programs with 15 steps)

• PID / ON/OFF switching / 3-way control

• 1 input, 7 outputs

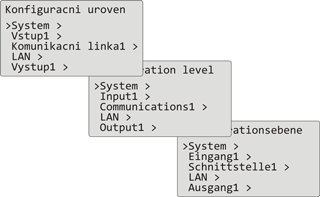

• LAN interface (on the rear panel)

• 2 communication lines EIA485

• 2 digital inputs

• datalogger of process values (500 logs)

• datalogger of messages (200 logs)

• datalogger of ambient temperature (500 logs)

• starting a program by the keyboard

• starting a program by real-time clock

• 3 years warranty

• guaranteed servicing

How to operate the controller

|

|

|

Controlling of stp point

|

• by program control (30 programs with 15 steps) • maintaining the set point Starting a program • starting a program by the keyboard • starting a program by real-time clock • by digital input • through the communication line |

|

Controlling

The controller can operate the thermal system with the following types of controllingí:

|

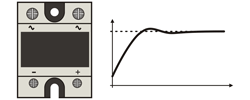

PID control This mode is most used. It enables controlling to zero deviation. As an output it can be applied solid-state, relay, voltage or current output. |

|

|

ON/OFF switching Simple way of controlling, it is not possible to reach the zero deviation. |

|

|

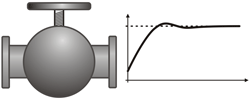

3-way step controlling PID control with 2 outputs for adjusting of valves. Position of the valve is calculated from the time of transition. |

|

Dataloggers in the controller

The controller Ht205 stores data into 3 dataloggers:

|

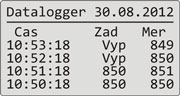

Datalogger of process values stores: • measured and set point value of the controller Ht205 • measured values from as many as 7 "Slave" controllers • status of the external energy meter • number of the running program Maximum amount of logs is 500. |

|

|

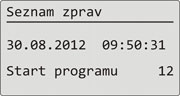

Datalogger of messages stores: • changes in the parameters setting in configuration and operation level • time of start / end or interruption of a program • exceeding of alarm limits • ... Maximum amount of logs is 200. |

|

|

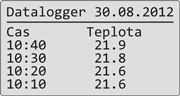

Datalogger of ambient temperature stores: • ambient temperature, it means the temperature at which the controller works Maximum amount of logs is 500. |

|

Stored values can be transferred though the communication line to PC.